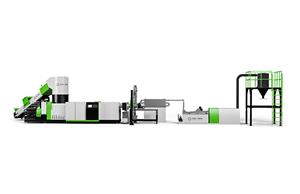

China PET Compacter and flakes pelletizing system Factory Price

PET Compacter and flakes pelletizing system

The company said it would add a new dedicated cleaning line, which is expected to be operational by the end of the year, so it can produce clean scales. Phoenix uses clean scales as raw material sand, creating its rPET, which is used to create packaged products such as beverages, food, personal care and home cleaners.

Before the cleaning line is installed, Phoenix either buys clean scales directly or recycles them from roadside recycled bottles and collects these materials for a third-party cleaning operation to make clean scales.

In preparation for upstream consolidation, Phoenix said it has been trying to diversify and strengthen supplier relationships over the past two years. The company's goal is to procure enough cotton bags and dirty cotton chips to meet the needs of a washing line with an estimated annual production of 50 million pounds. The company will purchase raw materials from the waste truck and material recovery facility (MRFs).

Lori Carson, director of business operations in Phoenix, said: "We believe we will have more snowflakes with the same quality consistency. "When we buy finished goods or services across suppliers and regions, we see differences in the quality of the finished product, whether it's availability from that region or from processor capabilities. "

She added: "We are just moving the location of the purchase material. While we want to grow over time, we now think it's an alternative, not a new pound, but from a different source. We expect our forecast range to be about the same as the level of the past four to five years. "

In addition, Carson said Phoenix will be able to grow its market as the company improves the quality of its materials.

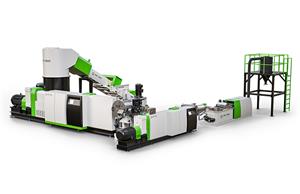

PET Compacter and Pelletizer Factory

"Combining the entire supply chain, from packaging to final products, and its processes will allow us to optimize washing and scale processing components, which we can't do when clean scales come from outside sources," said Bob Dearoff, president of Phoenix. The new production line will also enable Phoenix to fine-tune key manufacturing variables so that we can better provide valuable processing and performance attributes to our customers. "

The company says it also wants to better manage its environmental footprint, especially the water used in the production process and the fuel used for transportation.

According to a recent article in Business Week, pet maker OCTAL, "Food waste has become a major problem in the United States because of the cost of landfill transfer and maintenance." Last year, Americans threw away the equivalent of $180 billion in food, an 8% increase from 2008. 2008 was the last time the U.S. Department of Agriculture calculated total food losses for households, supermarkets, restaurants and other food service providers. "

The packaging is originally designed to keep food fresh for longer and to provide protection during transport. Both assets have helped to reduce the amount of waste entering landfills. BUT THE PACKAGING COULD STILL FAIL, LEADING TO A RESURGENCE OF ADDITIONAL WASTE, OCTAL SAID.

The right material selection helps ensure that the packaging fulfills its commitments. According to OCTAL, PET tablets provide many unique features for food packaging, one of the main advantages of which is mechanical robustness. PET sheet rigidity and toughness, with sufficient elasticity to prevent the packaging cracking, thus ensuring good transport performance. In addition, PET flakes provide lower oxygen permeability than other commonly used polymers, increasing shelf life for food, OCTAL said.

China PET flakes pelletizing system Price

Recycling plastic is currently one of the best ways to remove material from landfills. OCTAL points out that PET recycling boards have many advantages over the recycling of other plastic materials.

According to OCTAL, its DPET ™ is the world's first and only direct lycinal polyester film. The direct plate-making process is said to eliminate the five high-energy stages of the traditional platemaking process: granulation machine, SSP, compactor, dryer and extruder.

"Manufacturers of food packaged with OCTAL DPET have improved the integrity and performance of their packaging," said William J. Barenberg Jr., octAL's chief operating officer. In addition, DPET sheets combine sustainability, high consistency, easy molding, high mechanical yield and good aesthetics. "

OCTAL's DPET technology platform is said to provide products that protect food during transport, extend shelf life, and are easy to recycle, helping to reduce waste entering landfills.

Perhaps the biggest news of the event was Erema's first announcement in North America of a new global business unit focused on supplying the entire plastics recycling plant from a single source. Michal Prochazka is the head of Keycycle, which was founded in Austria a few months ago. He says the advantages of this new system integration service.